There are plenty of myths about electric vehicles (EVs), from how far they can go to what happens to their batteries at the end of their life. So, last week, the char.gy team hit the road to set the record straight. We travelled through Barnet, Richmond, Wandsworth, Tower Hamlets, Southwark, Merton, and Brighton & Hove, chatting with current (and hopefully future!) char.gy drivers about all things electric: the good, the bad, and everything in between.

But one myth seemed to follow us wherever we went: “Aren’t EVs worse for the environment because of the batteries?” It’s a tricky question, and one we’re always keen to answer.

At char.gy, we believe transparency matters. Whether it’s with our drivers, partners, or the wider community, we want to make sure people understand the full story behind electric driving. So, here’s the reality of EV battery disposal, recycling, and reuse, and how the industry is evolving for the better.

The Lifecycle Before ‘End of Life’

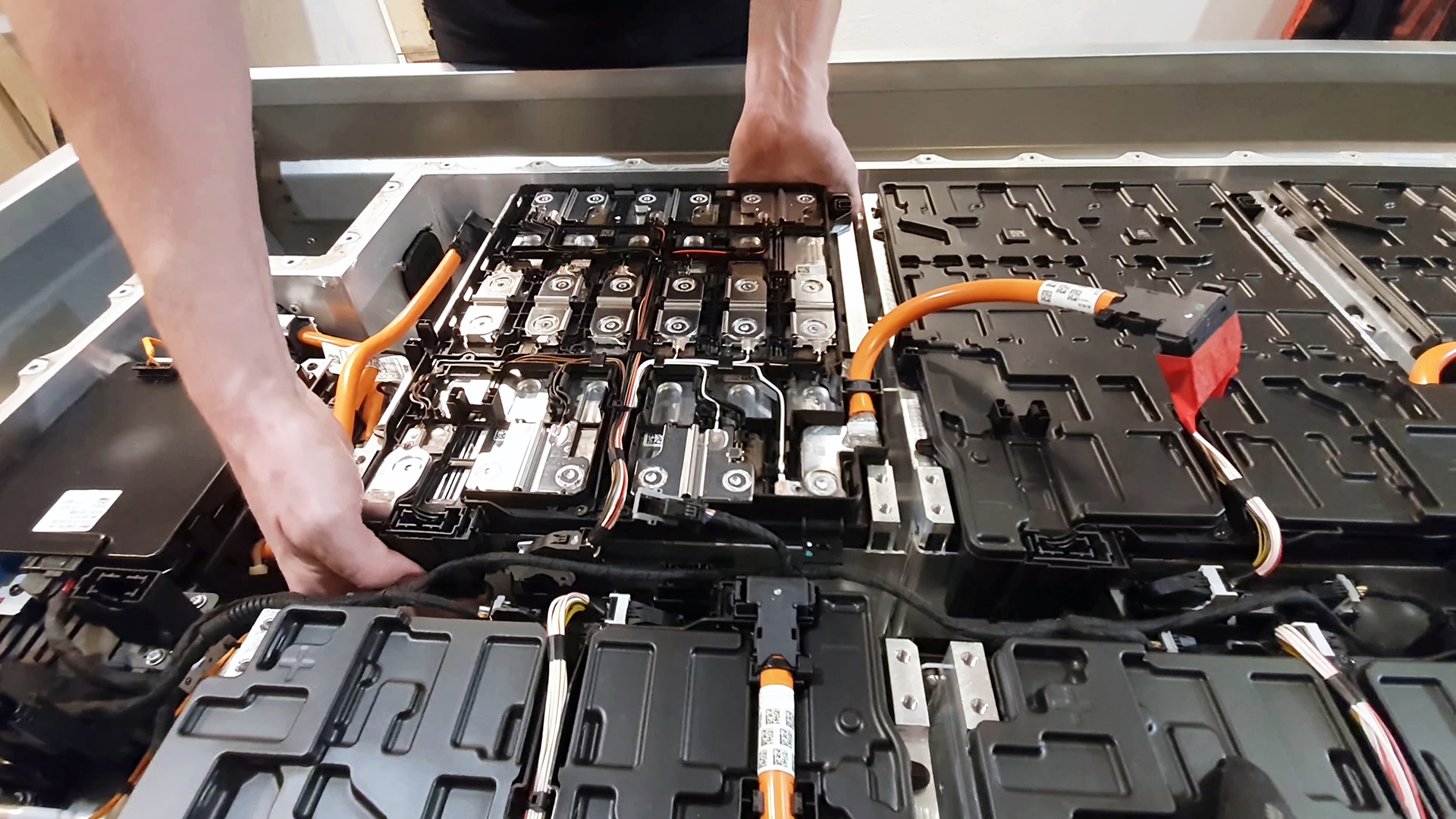

Before an EV battery retires, it’s already done years of service. Most outlive their manufacturer warranties, lasting around 12–15 years in moderate climates and 8–12 years in harsher ones. Even when a battery is no longer ideal for driving, it usually retains 70–80% of its original capacity, meaning it can still be useful, just not for propulsion.

1. Second Life: Repurposing EV Batteries

One of the most exciting developments is repurposing retired EV batteries for stationary energy storage. Instead of heading straight for recycling, batteries are tested, sorted, and reused for home storage, commercial backup, or grid-level systems. These “second life” applications help balance renewable energy supply by soaking up excess solar or wind power and releasing it when needed. This approach extends the battery’s life, supports a cleaner grid, and reduces the immediate demand for raw materials. While challenges remain, such as variability in battery chemistry and size, it’s a huge step toward circular energy use.

2. Recycling: Recovering Value, Protecting the Planet

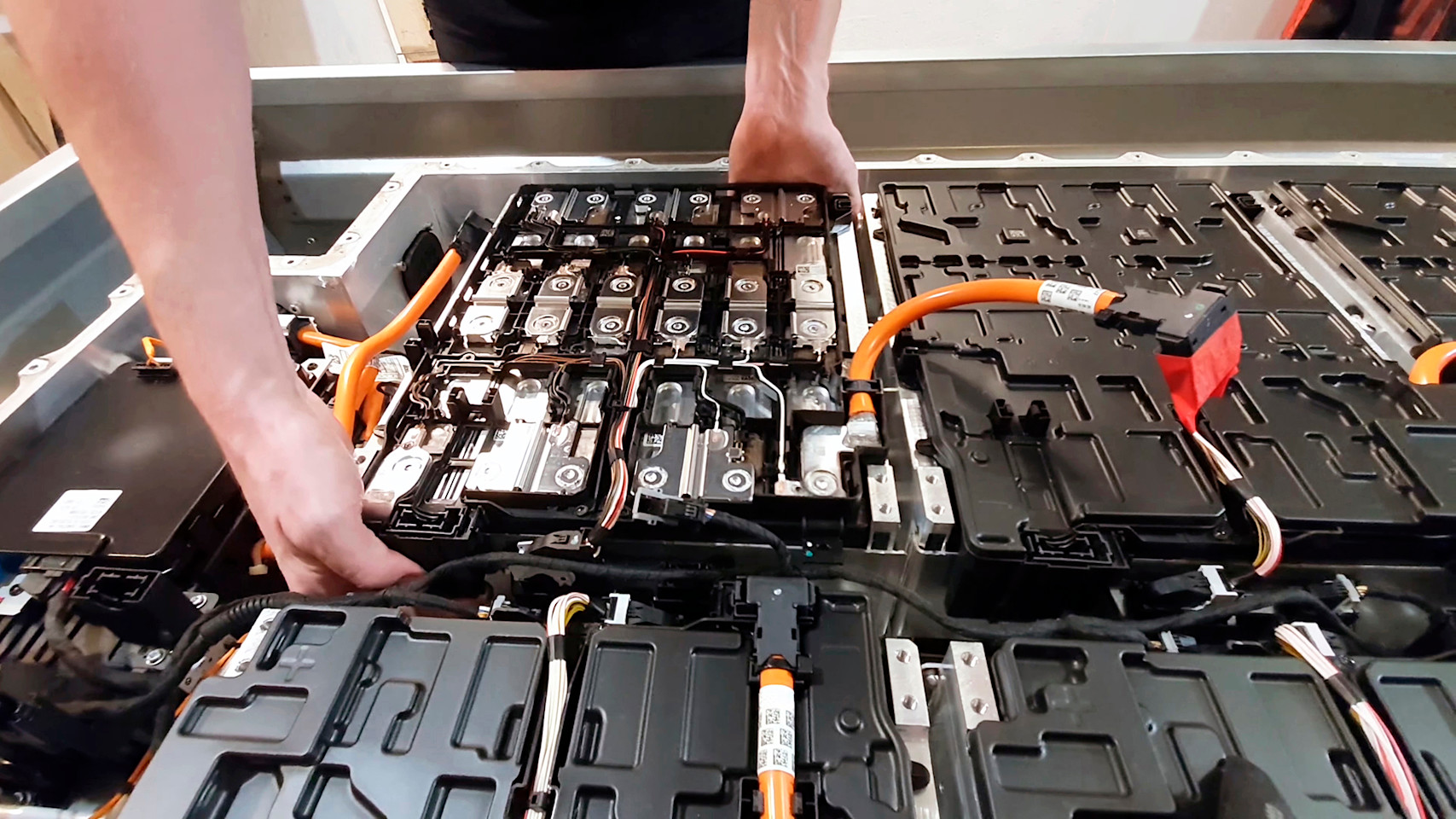

When reuse isn’t possible, recycling becomes essential, not just to prevent waste, but to recover valuable materials like lithium, cobalt, nickel, and copper. Current methods include:

Pyrometallurgical processing: Batteries are dismantled, crushed, and heated to extract valuable metals.

Hydrometallurgical processing: Chemicals are used to dissolve materials for recovery, often achieving higher yields and greater flexibility.

Innovations on the horizon:

Cleaner chemical processes that better recover lithium and aluminium.

Flash Joule heating, a new method using electric current to recover up to 98% of metals.

Robotic disassembly helps to safely automate the process and reduce labour costs.

These innovations mean recycling isn’t just about reducing harm; it’s about recovering value and closing the loop.

3. Avoiding Landfill: A Non-Negotiable

Dumping EV batteries in landfill is not only wasteful, it’s dangerous. Reactive materials like lithium can ignite or leak toxic substances into soil and water. Worse still, valuable metals are lost forever, increasing the need for new mining. That’s why strict regulations are being introduced to ensure proper collection, recovery, and recycling, making landfill disposal a thing of the past.

The Scale of the Challenge Ahead

By 2030, the UK is expected to generate around 28,000 tonnes of EV batteries for recycling, rising to 235,000 tonnes by 2040. Meeting that challenge means:

Rapidly scaling recycling capacity

Improving cost-efficiency

Strengthening regulation and recovery targets

The UK and EU are already setting ambitious goals, such as 70% lithium-ion recycling by 2031 and mandatory recycled content requirements for new batteries by the mid-2030s. Back to the Road People are curious, cautious, and want clarity, and that’s exactly what we aim to provide. Every myth we bust and every question we answer brings us closer to a more confident, informed, and electric community. At char.gy, we believe in EVery story, because real stories power real change.